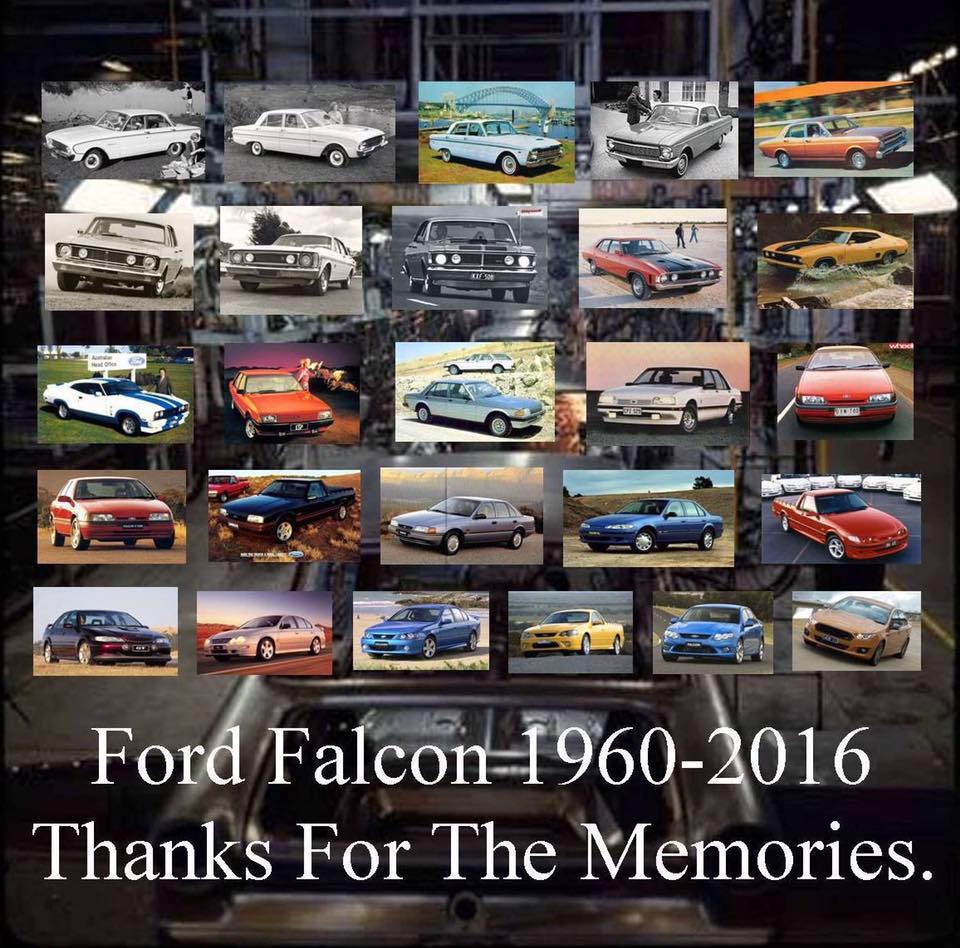

Falcon History 1960 – 2016

NEVER again will we see an Australian automotive dynasty like the one shared between Ford and Holden.

For much of the past century, the two marques have battled on the road and race track for sales supremacy. That duel has led to the Ford Falcon and Holden Commodore becoming part of our folklore.

Few families could say they have never had one of the two in their driveway over the past 50-odd years. Yet never both – families were staunchly Ford or Holden.

But the curtain call has sounded on the Ford Falcon. It will be first to exit the motoring stage when Ford Australia production ends in October 2016.

When Ford Australia closes its Broadmeadows and Geelong factory doors on 7th October 2016 it will bring to an end a local Blue Oval manufacturing tradition that began 91 years ago in 1925, when Model Ts were first assembled in a converted Geelong wool store.

The last vehicles to roll off the line were a Kinetic Blue XR6 sedan and a Winter White Territory. Neither vehicle will be registered or sold, but will instead be retained by Ford for display purposes.

The last two vehicles bring to 4,356,528 the number of Fords built at Broadmeadows between August 20, 1959 and October 7, 2016, including exports of vehicles like the Capri convertible.

In total, including at its plant at Eagle Farm in Brisbane, Ford Australia produced more than three million Falcon sedans and wagons, more than half a million Falcon Utes and between 1967 and 2008 more than 250,000 long-wheelbase Fairlanes and LTDs.

Ford is not alone, Holden and Toyota will also shut local manufacturing doors due to wide-ranging issues, including the strong Australian dollar, high labour costs here compared with overseas, changing buyer tastes and an intensely competitive market, with more than 60 different brands.

Back in the 1950s, initial plans had Ford looking at the likes of the Zephyr, Consul and Zodiac to lead its sales assault on Holden – which was dominating the market, partly due to Ford’s higher prices attributed to the import tariffs imposed on parts.

But when executives made a visit to Detroit in 1958, it was a pivotal moment in our history. There they saw the XK Falcon, which was launched in Australia two years later.

Under the bonnet was a 144 cubic inch (2.36-litre) overhead valve six-cylinder engine producing its 90 horsepower (67kW). It was able to reach 140kmh, about 10kmh more than the rival from Holden.

The 4.0-litre six-cylinder final FG-X Falcon launched last month generates 195kW.

Challenging rough-and-tumble Aussie roads had a negative impact on the American-sourced XK variant, which quickly heralded suspension changes that headlined the XL’s arrival two years later. That led to a watershed moment in 1964, when the XM was launched with an Australian-designed body.

Yet it was the next model the 1965 XP which really put the Falcon on the automotive map with the 70,000 mile endurance run over nine days with 5 XP Falcons on the You Yangs test track.

“They created some damage on the cars but in the end they all finished,” said Dan Bowden, a proud Blue Oval fan and a member of the Bowden Car Care family, which owns some of Australia’s most prestigious race and road cars. “There were rollovers… the whole lot, but they kept them going and ran non-stop. It was crazy back then for a manufacturer to take on something like that with all these young testosterone-fuelled race drivers. “It was a crazy idea but they pulled it off. They did some really good work on those cars (XPs) and they became more ‘Australianised’ and they are a very different car from the American Falcon.”

For the true Ford devotees, the love affair began in 1967 with the XR GT. That’s where the performance heritage of the brand was formed, courtesy of a 225bhp (168kW) 289-cu-in (4.7-litre) Windsor V8 engine, sourced from the Mustang.

Winning Bathurst, it was the first salvo in the Ford versus Holden muscle car war. The Mountain ultimately proved to be a pivotal marketing source for both brands, when the old adage of “win on Sunday, sell on Monday” came to the fore. Back in the ’70s the vehicles in showrooms were not vastly different from those on the track – apart from the roll cage.

Part of the Falcon’s appeal was the whole family could go along for the ride. The RACQ’s Joe Fitzgerald also has blue running through his veins. “I recall childhood road trips, roasting on the white-hot vinyl seats of our XC Falcon, with some fondness,” he said. “But anyone genuinely shocked that the Falcon will soon cease to exist simply hasn’t been paying attention. “The relegation of the once-mighty family car market to an also-ran meant the days of producing a vehicle with little global appeal were always going to be numbered.”

Local Ford production reached its peak in the early 1990s, when it was Australia’s biggest motor manufacturer with more than 14,000 staff working two shifts a day to produce up to 150,000 vehicles a year in Victoria, NSW and Queensland.

As well as the Falcon, Ford’s Homebush factory in Sydney’s west produced the Mazda-based Laser, which became Australia’s top-selling small car, before closing in 1994, while Brisbane’s Eagle Farm plant made Fairlanes, Galaxies, LTDs and Ford trucks before it was shut in 1998.

Annual Falcon production topped 100,000 for the last time in the mid-1990s, before Holden’s 1997 VT Commodore became Australia’s favourite car. Holden will follow Ford’s lead by ceasing Australian production at the end of 2017, following declining large-car sales for more than a decade.

While the Broadmeadows factory opened in 1960 by then prime minister Robert Menzies 2015 produced less than 8600 Falcon sedans and utes, and 8900 Territory SUVs, 2015 also saw Ford sell more than 30,000 examples of the Australian-engineered, Thai-built Ranger ute.

By 2010, like Toyota and Holden, Ford’s manufacturing future had been sealed by three decades of reducing import tariff protection, relatively high labour costs, recession, a soaring Aussie dollar and limited export opportunities.

Much of Ford’s production facilities will be decommissioned and – like Holden’s 37-hectare Port Melbourne facility – eventually sold off.

However, its former head office will be transformed into the Ford Asia-Pacific Product Development Centre, which together with its adjacent design studio will continue to design and engineer global and regional Ford models. Ford’s sales and marketing team moved to a new office in the Melbourne suburb of Richmond last year.

First Generation:

XK

Release: September 1960

Start of production: June 1960

End of production: July 1962

Production plants: Broadmeadows, Eagle Farm

Production volume: 68,453

The Falcon is introduced to the Australian market in September 1960. At the time it was described as a ‘compact’, as it was smaller than the popular family cars of the period.

XL

Release: August 1962

Start of production: July 1962

End of production: January 1964

Production plants: Broadmeadows, Eagle Farm

Production volume: 75,653

XL was first Australian car to offer seat belt mounting points and a padded facia for the dashboard.

Six XL Falcon convertibles were built and used during the 1962 Miss Australia Quest.

The job of designing the Falcon Hardtop Convertible went to Lewis Bandt, the father of the Ford Coupe Utility.

Falcon wins first major endurance car race at Phillip Island with XL Falcon taking first, second, third and fourth places in Class B. Harry Firth and Bob Janes’ XL Falcon number 21 was recognised as outright winner, the nearest Holden was 21 miles behind.

XM

Release: February 1964

Start of production: December 1963

End of production: February 1965

Production plants: Broadmeadows, Eagle Farm

Production volume: 47,103

The first Australian designed body, although very similar to its US parent, with its heavy chrome lip on three-bar grille.

First Falcon Tested and developed for Australian conditions, the vehicle was tested on the Eyre Peninsula in South Australia. Prototypes were tested in extreme conditions and resulted in more than 1500 modifications at a cost of one million pounds.

Fairmont and Futura Hardtop introduced.

XP

Release: March 1965

Start of production: September 1964

End of production: August 1966

Production plants: Broadmeadows, Eagle Farm

Production volume: 69,561

Bill Bourke had a vision to prove to the public that the Falcon was a tough, reliable vehicle suited to Australian conditions. A plan was devised to highlight this new vehicle. Five new Falcons were taken off the assembly line and driven a total of 70,000 miles in a durability run lasting nine days around the You Yangs Proving Ground. Bill Bourke’s vision succeeded when the vehicles beat the time limit and gained extensive publicity in the media. The event was commenced on April 24, 1965 and ran for almost nine days. The five stock standard Falcons crossed the finish line at 1:42am on May 3 after completing 70,000 miles at an average speed of more than 70mph, breaking 49 Australian endurance records. The extraordinary fact of this feat was that the cars competed over a testing and hilly test track and not on a circular track or even a standard race circuit.

Introduction of the Fairmont luxury model into the range.

XP Falcon named Wheels Car of the Year for 1965.

Second Generation:

XR

Release: September 1966

Start of production: June 1966

End of production: March 1968

Production plants: Broadmeadows, Eagle Farm

Production volume: 88,786

XR Falcon hailed as the “Mustang-bred Falcon” caught the motoring world by surprise with its new “coke bottle” styling and V8 engine option.

Hardtop is deleted from the range.

XR Falcon named Wheels Car of the Year for 1966.

In April 1967 the “muscle car” era starts with introduction of the

XR GT.

Due to increasing demand in New Zealand for Australia’s Ford Falcon, assembly from “Knocked down” packs started at Lower Hutt, near Wellington.

For the first time V8 muscle cars appear at the great race. XR Falcon GT’s take first and second place. Harry Firth and Fred Gibson take first place in car 52 and Ian and Leo Geoghegan take second place in car 53.

XT

Release: March 1968

Start of production: January 1968

End of production: June 1969

Production plants: Broadmeadows, Eagle Farm

Production volume: 74,392

XT GT boasted the biggest engine available in Australia – all 351 cubic inches and 290hp.

In 1968, Ford Australia made motoring history when its team of three near standard XT Falcon GTs were the first, second and third Australian cars home and finished third, sixth and eighth outright, winning the coveted Teams Prize in the London-Sydney Marathon, the world’s longest ever road event — a 17,000 km, 11-day motoring experience.

XW

Release: June 1969

Start of production: May 1969

End of production: October 1970

Production plants: Broadmeadows, Eagle Farm

Production volume: 93,129

Bolder styling, which featured raised ridges down each front guard and a “buttressed” C-pillar. A new dashboard and trim variations also appeared. Factory-fitted, fully integrated air conditioning was made available as an option for the first time. The GT variant gained a bigger V8, producing 291 horsepower (217 kW). The GT got a racing-style bonnet scoop, bonnet locks, and blackouts, as well as stripes along the full length of the car. GT-HO models added – 1969, Phase I and August 1969 Phase II. A homologation specially built for racing, HO officially stood for “Grand Tourer Handing Option” but its true meaning was “High Output”. The Phase I was fitted with the 351-cu-in Windsor V8, but was replaced a year later with the 351 Cleveland, producing 300 horsepower (220 kW) in the Phase II GT-HO. GT-HO Phase II’s take first and second at Bathurst. Allan Moffat takes outright first in car 64 and Bruce Mcphee takes second in car 63.

XY

Release: October 1970

Start of production: August 1970

End of production: May 1972

Production plants: Broadmeadows, Eagle Farm

Production volume: 100,474

Two new six-cylinder engines were designed and developed by Ford Australia engineers at the Geelong engine plant. The main characteristic of the new 200 CID (3.3-litre) and 250 CID (4.1-litre) engines is that they have a longer stroke and produce greater torque at low rpm.

In November 1972 Ford added Australia’s first production four-wheel drive utility to the Falcon range based on the XY. It was the first four-wheel drive passenger vehicle to be designed and built in Australia. Only 432 were ever built.

GT-HO Phase III released in 1970 was reputed to be the world’s fastest four-door sedan.

XY GT-HO Phase III’s dominate Bathurst. Allan Moffat successfully defends his title followed by followed by Phil Barnes and Bob Skelton in second, David McKay in third, John French in fifth and John Goss and Barry Sharp in sixth.

Third Generation:

XA

Release: February 1972

Start of production: December 1971

End of production: November 1973

Production plants: Broadmeadows, Eagle Farm

Production volume: 129,473

A milestone in the history of Ford Australia. This is the first time a Ford car has been completely styled, designed and fully manufactured in Australia. In every respect unique to Australia.

The XA introduced the locally built V8 engine, the optional 302 CID and 351 CID fully manufactured in the new V8 plant at Geelong.

Two-Door Hardtop re-introduced in August 1972, available in three models — the standard Falcon 500, the luxury Fairmont and the GT sports model.

Allan Moffat claims his third win at Bathurst in 1973 with co-driver Ian Geoghegan in an XA GT Hardtop. While there was a XA GT-HO planned, concerns about public safety due to climbing top speeds (manufacturers had to sell 200 of the model to make them eligible for Bathurst) saw only three race cars and one road going Phase IV built before the program was scuttled.

XB

Release: October 1973

Start of production: June 1973

End of production: June 1976

Production plants: Broadmeadows, Eagle Farm

Production volume: 211,981

Revised front and rear styling and many significant additions were added to the XB Falcon standard equipment list including front disc brakes, inertia reel seat belts, headlamp flasher/indicator and “friction disc” collapsible steering wheel.

Introduction of front disc brakes as standard on Falcon 500 models and for the first time four wheel disc brakes are being supplied by an Australian manufacturer, they will be available with all GT models.

John Goss and co-driver Kevin Bartlett win the 1974 Bathurst in an XA GT Hardtop, and despite Ford pulling out of racing, Allan Moffat continued to campaign the Falcon with his own team.

A limited edition XB Falcon Hardtop released in 1975 called the John Goss Special.

XC

Release: August 1976

Start of production: June 1976

End of production: July 1979

Production plants: Broadmeadows, Eagle Farm

Production volume: 171,080

GT was deleted from the range and the XC muscle car was the Cobra, released in August 1978, all were Falcon hardtops, each uniquely identified with a badge mounted in the glove box, numbered from 001 to 400.

Limited Edition Allan Moffat Special released.

Sundowner Van released.

Last of Hardtop.

In October 1976 XC Falcon GS Hardtop and Fairmont Hardtop released.

The XC Falcon GS 500 Hardtop also brought a famous 1-2 victory for Allan Moffat and Colin Bond at Bathurst in 1977.

In 1977 Falcon became Australia’s top selling car.

Fourth Generation:

XD

Release: March 1979

Start of production: February 1979

End of production: April 1982

Production plants: Broadmeadows

Production volume: 200,849

Falcon sedans fitted with new lightweight plastic fuel tank, the first mass-produced car in Australia to have this technology.

Henry Ford II visits Australia for launch of all-new XD Falcon, Fairlane and LTD range.

Hardtop deleted from the range.

Alloy head is introduced on XD in 1980.

This generation was a major change in styling, with better body reinforcing delivering weight savings along with improved all-round performance. While there were early issues with this model, Ford quickly ironed out the problems. Helping boost the appeal was Queensland driver Dick Johnson, who was a privateer who won the hearts of Ford lovers around Australia. His first XD was written off after hitting a rock at Bathurst, but public pledges enabled him to get racing again and he returned in a new Tru Blu XD Falcon, that won both Bathurst and two Australian Touring Car Championships.

XE

Release: March 1982

Start of production: December 1981

End of production: October 1984

Production plants: Broadmeadows

Production volume: 191,174

1982 Ford hits market leadership for the first time in its history in Australia.

Another chapter in the history of Ford in Australia was closed on November 25, 1982 when the last V8 engined Falcon rolled off the assembly line at the Ford Broadmeadows Assembly Plant.

This historic occasion was 50 years and three months to the day that the first Australian assembled Ford V8 went on sale August 25, 1932. The V8 was first offered as an option on the 1966 “Mustang-Bred” Falcon, a 289 CID V8, the first V8 engine ever offered in a locally built Ford car.

In February 1983 Electronic Fuel Injection (EFI) was announced to replace the V8 which had been dropped the prior year. Ford was the first Australian motor manufacturer to adapt one of its locally made car engines to fuel injection.

Australian Design Award is given to a motor vehicle for the first time to the XE Falcon / Fairlane / LTD range.

XF

Release: October 1984

Start of production: June 1984

End of production: October 1986

Production plants: Broadmeadows

Production volume: 178,028

The XF was notable for the introduction of Ford’s engine management system, EEC-IV, which was developed by Ford in the U.S. in 1982 and was adapted specially for Australian engines. The system added considerable processing power and extra control functions over fuel supply, ignition, idle speed, EGR valve and canister purging, and had a special “limp home” mode in the event of electronic malfunction.

In February 1985 the 1,500,000th Australian Falcon was produced.

Limited edition 25th Anniversary Falcon released, only 2000 released.

XFII

Release: October 1986

Start of production: September 1986

End of production: December 1987

Production plants: Broadmeadows

Production volume: 146,701

Utility XFII production continued until March 1993.

Broadmeadows Plant 2 started assembling utility in December 1987 and total utility production moved from Broadmeadows Plant 1 to Broadmeadows Plant 2 in January 1988.

Included in the total are 1951 Nissan Navarra utilities produced between May 1988 and October 1990.

When EA Falcon sedan was introduced the Falcon utility remained on the same platform until it realigned with the launch of the AU Falcon.

Fifth Generation

EA

Release: March 1988

Start of production: November 1987

End of production: November 1989

Production plants: Broadmeadows

Production volume: 118,859

$700 million investment and five-year development in the fully Australian designed EA Falcon.

New higher performance Ford 3.9-litre, overhead camshaft (OHC), fuel injected engine.

New economical 3.2-litre OHC engine.

The EA Falcon is the first locally built range of vehicles to offer rake- and reach-adjustable steering column. A joint development between Ford Australia and Tube makers of Australia.

The EA Fairmont Ghia is the first locally produced model equipped with a self-leveling rear suspension.

EAII

Release: October 1989

Start of production: August 1989

End of production: July 1991

Production plants: Broadmeadows

Production volume: 91,077

EAII introduced Australia’s first four-speed automatic transmission (BTR-85LE).

EAII introduced Australia’s first electronically controlled auto transmission.

In November 1989 the two millionth Australian-built Falcon rolled off the Broadmeadows assembly line.

EB

Release: July 1991

Start of production: April 1991

End of production: March 1992

Production plants: Broadmeadows

Production volume: 36,337

The V8 is re-introduced on the new XR8, after nearly nine years’ absence.

XG

Release: March 1993

Start of production: December 1992

End of production: March 1996

Production plants: Broadmeadows

Production volume: 24,592

Released in April 1993 as the Falcon Longreach GLi and S utility and the GLi panel van. The Longreach is the only passenger derived panel van available in Australia.

August 1993 one-tonne option released on Longreach.

EBII

Release: August 1992

Start of production: December 1991

End of production: August 1993

Production plants: Broadmeadows

Production volume: 84,874

First mainstream Australia sedan/wagon available with ABS brakes.

In 1992 Tickford release a limited edition 25th Anniversary GT based on the EB Fairmont Ghia. Only 250 were built for the Australian market. An additional 15 cars were built for new Zealand.

In 1992 Smart lock introduced.

Dick Johnson and John Bowe win 1994 Bathurst in EB Falcon.

ED

Release: August 1993

Start of production: June 1993

End of production: August 1994

Production plants: Broadmeadows

Production volume: 72,571

Revived a famous model name — Futura, model replaces “S”.

Immobilization and key less entry across all passenger variants.

ABS now standard on Fairmont and the new Futura.

XR6 and XR8 now with new nose styling incorporating four round recessed headlights.

Towing capacity increased from 2100 to 2300kg.

EF

Release: September 1994

Start of production: June 1994

End of production: September 1995

Production plants: Broadmeadows

Production volume: 97,524

The EF Falcon was developed over 3.5 years at a cost of $220 million.

Every panel and exterior feature on the sedans is new except the doors.

Henderson’s Automotive won the 1994 Engineering Excellence Award for Engineering Project Management in designing and developing the new front bucket seats for the EF Falcon.

Ford is first Australian manufacturer to use PBR Automotive new innovative park brake system which also won the 1994 Engineering Excellence Award.

Driver airbag introduced and fitted standard equipment on all models.

Ford developed the world’s first airbag-friendly protection bar (or bull bar).

EF Falcon range wins Australian Design Award of the Year for 1994.

EFII

Release: October 1995

Start of production: August 1995

End of production: September 1996

Production plants: Broadmeadows

Production volume: 88,420

First Australian manufacturer vehicle with standard driver airbag.

Passenger airbag is new, standard on Ghia and optional on other models.

EFII Falcon’s uniquely-shaped front passenger airbag option is designed to also give protection to the center occupant of the GLi’s no-cost-option centerfold bench seat.

EFII also offers improved suspensions.

EFII Ghia gains XR6 drive train, leather trim and CD player as standard.

EFII Fairmont Ghia gains passenger airbag, XR6 drive train, special lower suspension, leather trim and CD player all standard.

XH

Release: April 1996

Start of production: February 1996

End of production: October 1997

Production plants: Broadmeadows

Production volume: 15,361

In April 1997 a limited edition XH Series I Falcon Tradesman Ute was released, only 520 Falcon Tradesman utes to be built.

EL

Release: September 1996

Start of production: July 1996

End of production: August 1998

Production plants: Broadmeadows

Production volume: 140,795

The final facelift in the fifth generation, the $40 million EL program, brought further ride and handling improvements, latest generation ABS and an improved steering feel.

Ford first Australian manufacturer to offer a three-year/100,000km warranty.

Jason Bright and Steven Richards win 1998 Bathurst in EL Falcon.

In February 1997 Tickford release a limited edition 30th Anniversary GT based on the EL Fairmont. Only 250 were built for the Australian market, 116 automatic and 134 manual transmissions. An additional 20 cars were built for New Zealand with two vehicles also destined for South Africa.

XHII

Release: October 1997

Start of production: September 1997

End of production: May 1999

Production plants: Broadmeadows

Production volume: 12,996

In October 1997 the V8 option is released on the ute after a 15-year absence.

Falcon XR8 ute debuts with Ford’s best power/weight ratio. 185kW V8, 16-inch wheels, 50-series tyres and performance 3.45 LSD are features.

In April 1998 a limited edition XH Series II Falcon Tradesman Ute was released, only 700 Falcon Tradesman utes to be built.

Last van produced in April 1999.

Sixth Generation

AU

Release: September 1998

Start of production: June 1998

End of production: March 2000

Production plants: Broadmeadows

Production volume: 130,451

Controversial new shape delivers more space on the inside while being smaller on the outside. The higher roof line provides more interior headroom and there is much more luggage space in the boot. Signature design elements include large triangular headlights and tail-lights.

The big story is in the new suspension designs offering several multi-link suspension solutions. All models get the new double-wishbone front suspension, Euro shocks and linear rack-and-pinion steering system, which further enhances Falcon’s leading steering precision and front suspension control. Falcon Forte features Watts multi-link rear suspension while double wishbone multi link IRS is standard on Fairmont Ghia.

The new Intech engine retains the balance of an inline six and now wants to be revved above 3000rpm. The car delivers eight per cent better fuel economy and equals the economy of the 2.0-litre Escort of 1980.

First car in its class to offer air-conditioning and automatic transmission as standard equipment.

First locally developed, engineered and volume built independent rear suspension (IRS) in a rear drive car.

AU Falcon awarded the Australian Design Mark.

AUII

Release: April 2000

Start of production: February 2000

End of production: March 2002

Production plants: Broadmeadows

Production volume: 133,047

AUII was the first Australian built car with dual airbags as standard across the range.

The upgraded safety system also includes standard passenger airbags, a laminated impact protection panel to reduce foot well intrusion, wide ranging structural enhancements, energy management seat belt retractors, pyrotechnic seat belt buckle pretensioners and new technology airbag inflators.

Ford was the first manufacturer to offer dual fuel LPG as an option and in 2000 the first to offer Australia’s only factory-built range of Dedicated LPG vehicles.

First Australian-manufactured family car to offer a CD player as standard equipment across the range.

First Australian-manufactured family car to have 16-inch wheels as standard equipment across the range

First Australian-manufactured family car to feature a laminated firewall, which significantly reduces NVH.

The first Australian-made family car to include “Scheduled servicing to 60,000km” in the car’s purchase price

AUII safety package won the Gold Award at the Australian Society of Automotive Engineers’ 2001 Engineering Excellence Awards.

AUIII

Release: February 2002

Start of production: October 2001

End of production: September 2002

Production plants: Broadmeadows

Production volume: 59,340

ABS now standard on Forte which makes it standard across the Falcon passenger range.

The “Ford Racing” body kit is now standard on XR8.

BA

Release: October 2002

Start of production: July 2002

End of production: September 2004

Production plants: Broadmeadows

Production volume: 199,303

The $500 million BA development program focused on new engines and a highly sophisticated independent rear suspension delivering an outstanding motoring experience. new levels of occupant protection.

New passive safety elements include optional side airbags, dual stage front airbags, an intelligent crash sensor and restraint triggering system and a range of CAE-designed structural improvements.

Passive safety is enhanced, with sophisticated IRS, more powerful brakes with electronic brake distribution, steering refinements and interior ergonomics designed to keep a driver focused on the road.

First Australian-manufactured vehicle with Electronic Throttle Control (ETC), anti-intrusion brake pedal, power adjustable pedals, dual-stage inflatable airbags, on-screen antenna and optional pollen filter.

2003 Ford named Champion Manufacturer of the Year at V8 Supercar Championship awards.

BAII

Release: August 2004

Start of production: July 2004

End of production: October 2005

Production plants: Broadmeadows

Production volume: 81,894

New six-speed manual transmission in the XR6 Turbo and XR8 performance vehicles heads the list of changes.

The new Tremec T56 six-speed manual transmission with double synchros in all six forward gears adds the final touch to the performance line-up.

Futura safety levels were boosted significantly with the MkII version boasting side airbags as standard equipment.

2006 Craig Lowndes and Jamie Wincup take first place at Burthurst.

2005 and 2006 Ford named Champion Manufacturer of the Year at V8 Supercar Championship awards.

BF

Release: October 2005

Start of production: August 2005

End of production: September 2006

Production plants: Broadmeadows

Production volume: 63,050

Upgrades to the engines and transmissions powering the Falcon made noticeable improvements in performance, refinement and fuel economy in the petrol engines.

ZF 6HP26 six-speed automatic transmission introduced on premium Falcon sedans and utes with a host of dedicated software calibration.

Working with experts from the Bosch Automotive Chassis Systems Division, Ford calibrated a unique RWD application of DSC available on Fairmont Ghia, XR6 Turbo and the first application of Dynamic Stability Control in an Australian manufactured V8.

First six-speed automatic transmission on an Australian manufactured vehicle

First application of Dynamic Stability Control (DSC) on a V8-engined sedan and an Australian-manufactured vehicle with a manual transmission.

Ford LPG Challenge, after driving more than 13,950km around Australia for only $997.55 on fuel by filling up solely on LPG.

Ford named Champion Manufacturer of the Year at V8 Supercar Championship awards.

BFII

Release: August 2006

Start of production: August 2006

End of production: April 2008

Production plants: Broadmeadows

Production volume: 73,423

FPV rereleases F6 Typhoon.

2007 FPV release GT 40th Anniversary edition, only 200 were produced.

FPV released its new limited edition F6 R-Spec Typhoon in 2007, only 300 produced.

October 2007 FPV release limited edition GT Cobra and Cobra Ute. Limited to 400 sedans and 100 Utes.

Craig Lowndes and Jamie Whincup defend their title to take first place at Bathurst in 2007.

In October 2007 the first Ford 1-2-3 since 1988 as the #888 Team Vodafone Falcon driven by reigning Bathurst 1000 champions Craig Lowndes and Jamie Whincup crossed the line just seconds ahead of the #4 Jeld-Wen Racing Falcon of James Courtney and Dave Besnard, followed by the #17 Jim Beam Falcon of Steve Johnson and Will Davison.

April 2008 Ford release BF Falcon MkIII wagon.

Craig Lowndes and Jamie Whincup once again defend their title to take first place at Bathurst in 2008 for third year in a row.

2008 Ford named Champion Manufacturer of the Year at V8 Supercar Championship awards.

Seventh Generation

FG

Release: May 2008

Start of production: February 2008

End of production: November 2011

Production plants: Broadmeadows

Production volume: 144,587

FG Falcon is the first Australian-built car to receive a five-star safety rating from the Australasian New Car Assessment Program (ANCAP).

2008 Craig Lowndes and Jamie Whincup once again defend their title to take first place at Bathurst for third year in a row.

2009 Ford named Champion Manufacturer of the Year at V8 Supercar Championship awards.

July 2010 Ford release limited edition 50th Anniversary Falcon range.

Last wagon produced September 2010.

October 2010 FPV launch the first supercharged V8-engined GT in the 43-year history of the performance nameplate. FPV’s high-tech, all-new, supercharged 5.0 litre V8 engine produces 335kW of power and 570Nm of torque, and is standard fitment across the GT, GT-P and GT E models.

FG Falcon Ute achieves five-Star ANCAP safety rating for to all FG Falcon Ute models fitted with head and chest-protecting side airbags, Dynamic Stability Control (DSC) and a floor-mounted transmission lever – side airbags and DSC are both standard equipment on XR6 and XR6 Turbo models, and available as options on XL and R6 models.

FGII

Release: October 2011

Start of production: August 2011

End of production: October 2014

Production plants: Broadmeadows

Production volume: 46,727

FPV releases GS sedan and Ute as permanent additions to the niche manufacturer’s V8-engined range. The GS’s all-new lightweight supercharged V8 engine, developed and hand-assembled locally, produces 315kW of power and 545Nm of torque.

Mark Winterbottom and Steven Richards take first place at Bathurst in 2013.

Limited edition FPV GT F Sedan released in 2014 and was limited to just 550 units, 500 in Australia and 50 for New Zealand. 120 high-performance V8 Pursuit utes also.

Chaz Mostert and Paul Morris take first place at Bathurst in 2014.

FG-X

Release: September 2014

Start of production: August 2014

End of production: October 2016

Production plants: Broadmeadows

Production volume: 11,570

FG-X Falcon, Falcon Ute and Territory were the first Australian-built vehicles with SYNC2 with Emergency Assistance as standard across the range.

Limited Edition XR Sprint released. 1400 Falcon Sprints were built with 550 being XR6 Sprints and 850 XR8 Sprints. New Zealand allocated 150 cars – 50 XR6 Sprints and 100 XR8 Sprints.

April 2015 satellite-navigation fitted as standard across Falcon FG-X and Territory SZII range.

Falcon XR6 Sprint sports Ford’s first carbon-fibre engine air-intake system.

Falcon is only Australian ute to stay in production with unbroken model line after Holden withdraws WB series in 1985.

Falcon becomes the longest running vehicle name in Australian motoring history, and is the longest running car nameplate still in production in the 113-year history of the Ford Motor Company. Across all vehicles it sits behind only the F-Series, which was first introduced in 1948, and the Lincoln Continental, which was produced from 1939-2002.

Last Falcon produced on October 7, 2016.

FORD FACTS

- Ford Australia was founded in Geelong, Victoria, in 1925.

Total Falcon sedan and wagon production: 3,005,880

Total Falcon Ute and Van production: 572,809 - The Ford Falcon is Australia’s longest-running vehicle nameplate.

- The XF was the most number produced model Falcon (325,000)

*Information sourced from Drive.com.au